|

||||||||||||

|

|

||||||||||||

|

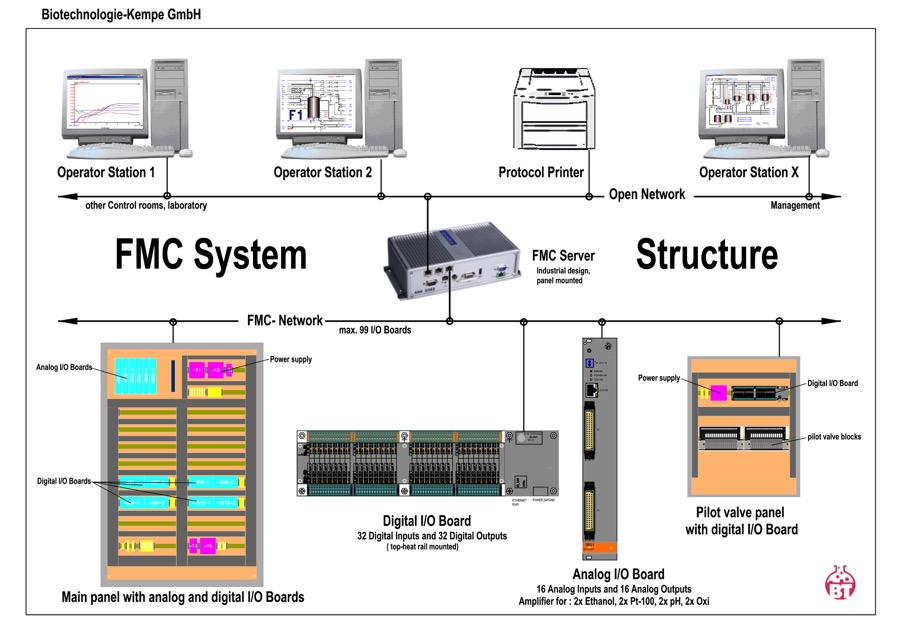

Process control by FMC - System |

||||||||

|

The claim of process control in research departments and in industrial applications is the availability of control programs, which can be modified easily by the user according his requirements. The process control with the FMC-System is realized by a dialogue between the user and the computer. This means, that based on the data of the past processes as well as of the actual, all provided from the system, the user decides how to run and control the next process. In this way the process is optimized stepwise. There is no knowledge of programming necessary for handling the FMC System. The process control with the FMC-System is shown here with the technology of baker ´s yeast production as example. The continuous measurement of the ethanol concentration with the SILICON-TUBING-PROBE serves as base for optimizing this fermentation process. Due to the discontinuous course of the process the use of the output signal ( alcohol concentration) as actual value is difficult, since the controller have a tendency to override, so good results are only given in the second half of fermentation process. |

||||||||

|

||||||||

|

With the FMC System a program for substrate feed has been designed, which controls the set-point value of alcohol concentration. So the substrate consumption can be optimized and the yield can increase considerably. By means of the FMC System for complete process automation following advantages are given:

With the FMC-System following control loops of each fermenter can be controlled:.

Alarm functions are activated by the FMC System in case of measuring value is exceeded or has fallen below and in case of male function of controllers. Other process units, i.e. molasses treatment, CIP- station, separation and yeast cream tanks, can be controlled and supervised by the FMC-System also. Additional to the measuring and control functions the FMC System provides a convenient data analysis program, for acquisition of process data (on-line) as well as of laboratory data (off-line). All data are managed in a database and can be used with other computer systems also.

|

||||||||